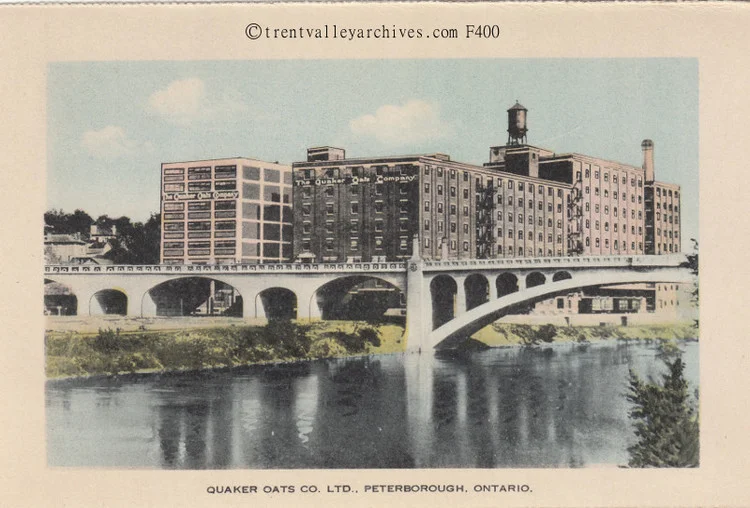

In 1993, the local engineering society prepared a plaque that is now mounted on the railing saying this is an unreinforced concrete bridge. The Professional Engineers of Ontario describe the distinction as follows: “The principal stresses in this arch are compressive stresses due to the dead load and are never neutralized or reversed by live loads or temperature stresses. Consequently, the entire rib is always in compression and there is no reinforcing whatsoever in the ring of the river arch.”

PtboCanada

Upcoming Events

sponsored by

Featured

PTBOCANADA is a website about Peterborough, Ontario, Canada. Copyright ©2010-2022, PTBOCANADA Media Inc. All rights reserved.